Arduino Opta Industrial Automation A Deep Dive

Arduino Opta industrial automation is revolutionizing manufacturing processes. This approach leverages the versatility of Arduino microcontrollers to seamlessly integrate with Opta systems, enabling enhanced automation and control. From precise data acquisition to robust motor control, Arduino’s adaptability empowers industrial operations with efficiency and precision.

This exploration delves into the practical applications, highlighting the integration process, and showcasing real-world case studies. We’ll also examine the advantages and disadvantages, comparing Arduino to other microcontroller platforms, and discuss safety protocols and future trends.

Introduction to Arduino in Industrial Automation

Arduino microcontrollers have emerged as a popular choice for incorporating programmable logic into various industrial automation tasks. Their affordability, ease of use, and extensive online support make them a valuable tool for prototyping and implementing smaller-scale automation projects. However, their limitations in terms of processing power and real-time performance need to be considered alongside the advantages when selecting them for a given application.The versatility of Arduino platforms allows them to be integrated into diverse industrial settings, controlling machinery, monitoring processes, and interacting with other equipment.

Their inherent advantages and disadvantages influence their suitability for different automation applications, as detailed in the following sections.

Arduino’s Role in Industrial Automation

Arduino’s primary role in industrial automation is as a versatile and cost-effective controller for tasks requiring real-time input/output management and simple logic. They excel in applications where precise timing and complex algorithms are not crucial, but where quick prototyping and modification are important.

Advantages of Using Arduino in Industrial Settings

Several factors contribute to Arduino’s appeal in industrial automation. Its affordability makes it attractive for initial project development and prototyping. The vast community support, extensive libraries, and user-friendly programming environment expedite development cycles. The open-source nature of the platform encourages customization and modification to suit specific needs.

Disadvantages of Using Arduino in Industrial Settings

Despite its benefits, Arduino has limitations. Its relatively lower processing power and limited memory compared to dedicated industrial controllers might be inadequate for demanding real-time applications. The lack of built-in safety features, such as fail-safe mechanisms, might be a concern in safety-critical applications. The lack of robust industrial-grade certifications can pose challenges in stringent regulatory environments.

Suitable Industrial Automation Applications

Arduino is well-suited for a variety of industrial applications. These include simple machine control systems, data acquisition and logging for monitoring processes, basic robotic control, and prototyping of automation systems.

Common Hardware Components Used with Arduino

Arduino projects in industrial automation often utilize various hardware components. Sensors such as temperature, pressure, and proximity sensors are frequently integrated to monitor and control processes. Actuators, such as motors, solenoids, and relays, are crucial for implementing automated actions. Communication modules, like Ethernet shields and serial interfaces, facilitate communication with other devices and systems.

Comparison of Arduino with Other Microcontroller Platforms

| Feature | Arduino | Alternative 1 (e.g., STM32) | Alternative 2 (e.g., Raspberry Pi) |

|---|---|---|---|

| Cost | Low | Medium | Medium-High |

| Processing Power | Moderate | High | High |

| Memory | Limited | Moderate to High | High |

| Real-time Performance | Moderate | High | Variable |

| Ease of Use | High | Medium | Medium |

| Community Support | Extensive | Good | Good |

Arduino’s suitability depends on the specific requirements of each project. For instance, a simple conveyor belt control might be effectively handled by an Arduino, while a sophisticated robotics system would likely benefit from a more powerful microcontroller platform.

Opta Integration and Applications

Opta, a frequently encountered acronym in industrial automation, often represents a specific platform or suite of tools designed for streamlining and optimizing industrial processes. This could involve managing machinery, controlling workflows, or monitoring production lines. Understanding Opta’s specific features and functionalities is key to effectively integrating Arduino into its ecosystem.Integrating Arduino with Opta systems allows for the creation of dynamic and adaptable automation solutions.

Arduino’s versatility in handling sensors and actuators, coupled with Opta’s comprehensive control capabilities, empowers engineers to develop tailored solutions for diverse industrial needs. This synergy facilitates a high degree of customization, enabling real-time data acquisition, precise control, and enhanced efficiency in industrial automation processes.

Arduino Integration with Opta Systems

Opta systems frequently feature APIs or communication protocols. Utilizing these interfaces allows seamless data exchange between Arduino and Opta, enabling Arduino to act as a data source or control point within the broader Opta ecosystem. This integration often involves programming Arduino to collect data from sensors, transmit it to the Opta system, and then receive commands for actuators or processes managed by Opta.

Real-World Industrial Automation Applications

Several real-world applications benefit from integrating Arduino with Opta. A common example is a smart factory floor where Arduino-controlled sensors monitor equipment health. Data from these sensors, transmitted through the Opta system, can trigger preventative maintenance schedules, minimizing downtime and maximizing productivity. Another example is in packaging lines, where Arduino can precisely control the speed and positioning of robotic arms, ensuring efficient and high-quality packaging.

Data Acquisition and Control in Opta Systems

Arduino excels at data acquisition. Equipped with various sensor interfaces (e.g., analog-to-digital converters), Arduino can monitor temperature, pressure, humidity, and other critical parameters in real time. This acquired data is then relayed to the Opta system for analysis and decision-making. Opta, in turn, can send control signals to Arduino-controlled actuators, enabling adjustments to machine settings based on real-time data or pre-programmed rules.

Potential Challenges in Integrating Arduino with Opta Systems

Integrating Arduino with Opta systems can present certain challenges. Compatibility issues between Arduino’s communication protocols and Opta’s system architecture are a common concern. Ensuring sufficient processing power on the Arduino board to handle data acquisition and control tasks is also crucial. Lastly, the complexity of the Opta system and the specific needs of the application may require significant development time and expertise.

- Compatibility Issues: Opta systems often use specific communication protocols. Matching Arduino’s communication methods to Opta’s requirements is essential to ensure smooth data flow. This might involve utilizing serial communication, Modbus, or other protocols, demanding careful consideration of the chosen protocols.

- Processing Power: Arduino’s processing capabilities might be insufficient for complex data acquisition and control tasks in large-scale Opta systems. Engineers must evaluate the computational load and potentially consider more powerful microcontrollers or additional processing units.

- Development Time and Expertise: Integrating Arduino with Opta systems demands a certain level of technical proficiency. The complexity of the Opta system and the application’s unique needs may necessitate extensive development time and specialized knowledge to achieve optimal integration and performance.

Specific Industrial Automation Tasks with Arduino

Arduino’s versatility makes it a compelling choice for various industrial automation tasks. Its relatively low cost, ease of programming, and extensive online support contribute to its popularity in these applications. Its ability to interface with diverse sensors and actuators enables automation of processes previously requiring more complex and expensive systems.The integration of Arduino into industrial automation systems often involves managing real-time data from sensors, controlling actuators, and communicating with other devices on the network.

This process typically involves a combination of sensing, processing, and actuating, enabling the automation of tasks that previously required manual intervention.

Common Industrial Automation Tasks, Arduino Opta industrial automation

Arduino excels in performing a range of tasks in industrial automation. These tasks often involve data acquisition, control, and communication. Typical examples include monitoring environmental conditions, controlling machinery, and automating production processes.

Sensors Used with Arduino

A wide array of sensors can be integrated with Arduino for industrial automation. Choosing the appropriate sensor depends on the specific application requirements.

- Temperature Sensors: These are crucial for monitoring and controlling temperature-sensitive processes. Examples include DS18B20, which provides high accuracy and a digital output.

- Pressure Sensors: Used to measure pressure changes in various applications, like hydraulic systems or pneumatic systems. The BMP280 is a good example of a sensor combining pressure and temperature readings.

- Proximity Sensors: Essential for detecting the presence or absence of objects. These are useful in tasks like counting items or detecting obstacles in robotic applications.

- Light Sensors: Used to detect changes in light intensity. Examples include photoresistors, suitable for applications like automated lighting or object counting.

- Motion Sensors: These sensors can detect movement or acceleration. Examples include accelerometers and gyroscopes, vital for applications such as robotic navigation or monitoring machinery vibrations.

Arduino Code Examples

Demonstrating specific code snippets for diverse tasks would require more detail about the particular application. However, a basic example showcasing temperature monitoring is provided.“`C++#include

Arduino and Industrial Communication Protocols

Arduino can be integrated with industrial communication protocols to facilitate communication with other devices or systems. A common example is Modbus, a widely used protocol in industrial settings. Libraries exist for Arduino to handle Modbus communication.

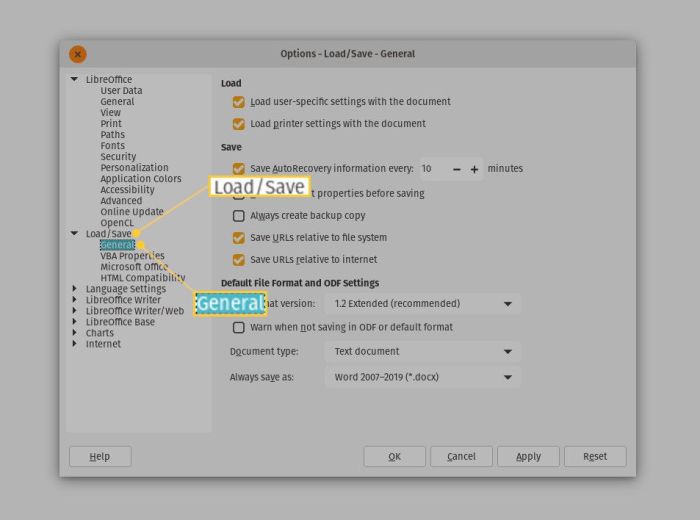

Controlling a Motor with Arduino and Opta

A flowchart illustrating the process of controlling a motor using Arduino and Opta is presented below. This example focuses on a simple on/off control mechanism.“`[Start] –> [Read Input from Opta] –> [Check if Motor Command is ON] –> [Yes: Activate Motor Driver] –> [No: Deactivate Motor Driver] –> [Update Opta with Motor Status] –> [End]“`This flowchart demonstrates the basic steps involved in controlling a motor using Arduino and Opta.

Opta provides the initial command, and Arduino executes the control action. The Arduino sends the motor status back to Opta.

Safety and Reliability in Industrial Automation with Arduino

Source: datocms-assets.com

Implementing Arduino in industrial automation offers significant advantages, but safety and reliability are paramount. Careful consideration of potential hazards and robust system design are crucial to ensure safe operation and maintain consistent performance in demanding environments. This section details key safety considerations, reliability methods, and error handling strategies for successful Arduino-based industrial automation projects.Ensuring the safety and reliability of Arduino-based industrial automation systems requires a multifaceted approach, encompassing careful selection of components, adherence to safety protocols, and the implementation of robust error handling mechanisms.

The correct application of these techniques guarantees the system’s continued operation and security, preventing costly downtime and potential hazards.

Safety Considerations in Industrial Settings

Safeguarding industrial automation systems is essential to prevent accidents and maintain a secure work environment. Prioritizing safety involves risk assessments, adherence to industry standards, and proactive measures for hazard mitigation.

- Hazard Identification and Risk Assessment: Thorough risk assessments are critical to pinpoint potential hazards associated with the Arduino-based system. This includes identifying potential sources of electrical shock, mechanical injury, and the impact on the surrounding environment. A comprehensive assessment is vital to mitigate these risks effectively.

- Compliance with Safety Standards: Adherence to relevant industry safety standards, such as those defined by organizations like UL or IEC, is mandatory. This ensures the system’s components and design meet the required safety benchmarks. Using approved components is crucial for compliance.

- Protective Measures: Implementing safety features, like enclosures, interlocks, emergency stops, and safety relays, is essential to prevent unintended operation and protect personnel from harm. These safeguards are vital for a secure operational environment.

Methods for Ensuring Reliability

Reliability in industrial automation systems is critical for consistent operation and minimal downtime. Various methods contribute to this reliability.

- Component Selection: Choosing high-quality, industrial-grade components with proven reliability is paramount. These components should be robust enough to withstand harsh industrial environments and have a track record of reliable performance. This includes selecting components designed for the specific voltage and current demands of the system.

- Redundancy and Backup Systems: Implementing redundant components or backup systems can mitigate the impact of component failures. This approach ensures continued operation even when a critical component fails. For instance, having a backup power supply for critical operations is a good practice.

- Regular Maintenance and Calibration: Implementing a routine maintenance schedule is vital for detecting and resolving potential issues before they escalate. Calibration procedures ensure accurate measurements and maintain system accuracy over time. Regular testing of critical components prevents unforeseen issues and maintains the system’s reliability.

Error Handling and Fault Tolerance

Robust error handling and fault tolerance are essential for ensuring that Arduino-based industrial automation systems can gracefully manage unexpected events.

- Error Detection and Logging: Implementing error detection mechanisms, such as checking sensor readings or communication signals, and logging errors, is critical. This enables quick identification of problems and allows for timely corrective actions. Real-time monitoring of critical parameters is crucial.

- Fault Isolation and Recovery: Developing algorithms for isolating faulty components or modules allows for targeted repairs. Having procedures to automatically recover from errors is also vital. This could involve switching to backup systems or resetting the system to a known good state.

- Graceful Degradation: Designing the system to continue operating with reduced functionality if a critical component fails is a vital part of fault tolerance. For example, the system could continue to function with reduced output or a subset of its original capabilities.

Real-World Safety Protocols

Industrial Arduino projects frequently employ safety protocols to ensure personnel safety and equipment protection.

- Safety Interlocks: Safety interlocks are often used to prevent hazardous conditions from arising. For instance, if a robot arm is in motion, an interlock might prevent access to the area where the arm is operating.

- Emergency Stop Systems: Emergency stop systems provide a rapid means of stopping potentially hazardous operations. They are essential in safeguarding against unexpected occurrences. These systems need to be easily accessible and clearly marked.

- Barrier Systems: Barrier systems are implemented to restrict access to potentially hazardous areas or equipment. This is particularly important in situations involving moving parts or high-voltage components.

Robust Communication Protocols

Reliable communication between Arduino and Opta systems is critical for seamless integration and effective control.

- Modbus: Modbus is a widely used communication protocol in industrial settings. It provides a reliable method for data exchange between devices.

- OPC UA: OPC UA is another common communication protocol that allows for the exchange of data between diverse automation systems. This standard enables interoperability and data exchange between different systems.

- Custom Protocols: For specific applications, a custom protocol might be developed to optimize communication efficiency. This approach is particularly useful when specific requirements are not addressed by existing standards.

Future Trends and Developments: Arduino Opta Industrial Automation

The landscape of industrial automation is rapidly evolving, driven by technological advancements and a growing need for efficiency and precision. Arduino, with its versatility and affordability, is poised to play a crucial role in this evolution, particularly in conjunction with the Opta industrial automation platform. This section explores emerging trends and developments, focusing on the integration of AI, cloud computing, and cutting-edge sensors with Arduino-based systems.The convergence of Arduino’s capabilities with advanced technologies is creating new possibilities for automation in diverse industrial sectors.

This integration will lead to more sophisticated and responsive systems, ultimately improving operational efficiency and reducing costs.

AI and Machine Learning Integration

The incorporation of artificial intelligence (AI) and machine learning (ML) into Arduino-based automation systems is a significant trend. AI algorithms can analyze sensor data in real-time, enabling predictive maintenance, optimizing process parameters, and automating complex tasks. For instance, AI-powered anomaly detection systems can identify potential equipment failures before they occur, minimizing downtime and maximizing operational efficiency.

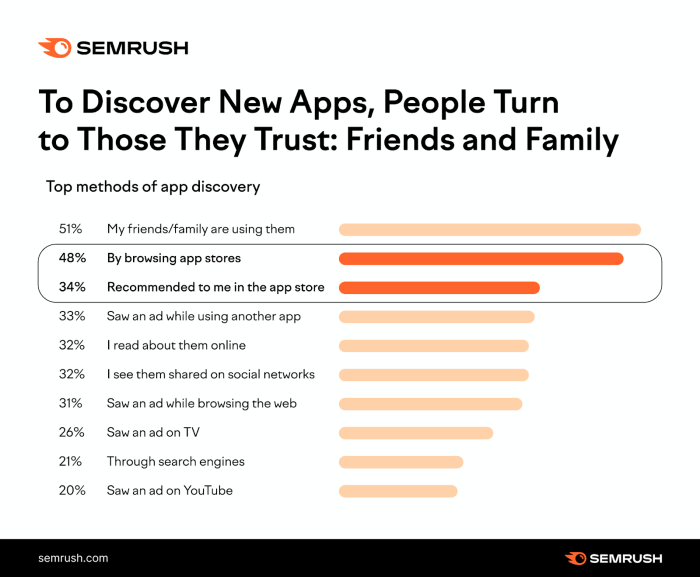

Cloud Computing Integration

Cloud computing is increasingly integrated into industrial automation systems, offering advantages like remote monitoring, data analysis, and enhanced scalability. Arduino-based systems, when coupled with Opta, can transmit real-time data to the cloud, enabling remote diagnostics and control. This facilitates real-time monitoring and management of industrial processes, enhancing overall productivity and allowing for proactive maintenance schedules. Data collected from multiple automated systems can be aggregated and analyzed, providing valuable insights into production patterns and potential areas for improvement.

Advancements in Sensors and Actuators

New sensors and actuators are constantly being developed, providing enhanced precision, accuracy, and connectivity. The use of advanced sensors, such as those measuring pressure, temperature, and vibration with greater accuracy and reliability, is becoming more prevalent. These advancements allow for more sophisticated control loops and improved process control, resulting in increased quality and output. Examples include high-resolution image sensors for quality control, and advanced motion control actuators for precise robotic movements.

Future Research Areas

Several potential areas for future research in Arduino-based industrial automation with Opta include:

- Developing robust cybersecurity protocols to protect industrial automation systems from cyber threats.

- Improving the real-time performance of AI algorithms running on Arduino-based platforms, enhancing the responsiveness of automated systems.

- Exploring the application of advanced machine learning algorithms for predictive maintenance in more complex industrial processes.

- Optimizing the integration of cloud-based data analysis tools with Arduino-based systems for more efficient data management and processing.

Detailed Case Studies of Arduino Opta Integration

Integrating Arduino with Opta systems offers significant advantages in industrial automation, enabling flexibility, cost-effectiveness, and enhanced control. These integrations often result in improved process efficiency, data insights, and remote monitoring capabilities. Real-world case studies highlight the practical applications and benefits of this approach.

Automated Packaging Line Control

This case study details a successful application of Arduino-Opta integration in a packaging line. The integration automates the control of the entire packaging process, including product loading, sealing, and labeling. Using Arduino, the system monitors product placement accuracy and adjusts the conveyor speed dynamically to maintain optimal throughput. Opta provides the central control and data management platform, allowing for real-time monitoring and analysis of the packaging line performance.

A key aspect is the integration of sensors on the packaging line, providing feedback to the Arduino system. This feedback allows for precise control of the entire process.

Data Logging and Analysis for Machine Health Monitoring

This project utilizes Arduino for data logging and analysis, focused on machine health monitoring in a manufacturing setting. Sensors on various machinery components, such as motors and bearings, collect data on vibration, temperature, and current draw. Arduino processes this data, sending it to an Opta system for storage and analysis. The system can detect anomalies in machine performance, enabling predictive maintenance, reducing downtime, and maximizing equipment lifespan.

The Opta platform allows for visualization of collected data, creating reports, and identifying trends.

Remote Monitoring and Control of a Water Treatment Plant

This case study demonstrates the application of Arduino and Opta for remote monitoring and control in a water treatment plant. Arduino-based sensors monitor critical parameters such as water flow rate, pH levels, and chlorine concentration. These sensors communicate with an Opta system for centralized data collection and analysis. The Opta system provides remote access for operators to monitor plant performance, adjust parameters, and receive alerts for potential issues.

This remote capability enables proactive management, reducing the need for frequent on-site visits.

Optimized Efficiency in an Industrial Production Line

This case study examines how Arduino optimized efficiency in an industrial production line. The system used Arduino-controlled robots for parts assembly, enabling adjustments in real-time based on sensor data. Opta integrated these robot movements with other processes on the production line, such as material delivery and quality checks. This resulted in increased throughput and reduced production time, while maintaining high product quality.

Real-time data analysis on the Opta platform pinpointed bottlenecks and enabled immediate process adjustments. The implementation showcased a significant improvement in operational efficiency.

End of Discussion

Source: cytron.io

In conclusion, Arduino Opta industrial automation offers a compelling path toward optimized and adaptable industrial processes. The integration of Arduino’s flexibility with Opta’s capabilities opens doors to enhanced precision, efficiency, and safety. The future looks promising, with AI and cloud computing poised to further augment these capabilities.

Post Comment