How Weather Affects Electric Car Performance

How weather affects electric car performance is a crucial consideration for drivers and manufacturers alike. From frigid temperatures impacting battery performance to the effects of rain and wind on range and aerodynamics, understanding these factors is key to maximizing electric vehicle efficiency and safety in various conditions. The performance of electric vehicles is significantly influenced by the surrounding environment.

This discussion explores the multifaceted relationship between weather and electric car performance, examining the impact of temperature, humidity, precipitation, wind, tires, charging infrastructure, and even driver behavior. We’ll delve into the science behind how weather affects battery chemistry, motor efficiency, and overall vehicle range, providing practical insights for electric vehicle owners and enthusiasts.

Impact of Temperature on Battery Performance

Source: co.nz

Electric vehicle batteries, predominantly lithium-ion, are susceptible to performance variations based on environmental temperatures. Understanding these temperature effects is crucial for optimizing battery life and range, as well as for developing effective strategies to mitigate these impacts. Different temperatures influence the chemical reactions within the battery, affecting its overall capacity and charging speed.

Temperature Effects on Battery Chemistry

Battery performance is intrinsically linked to the chemical reactions occurring within the battery cells. These reactions are sensitive to temperature changes. Increased temperature accelerates the rate of these reactions, potentially leading to faster charging but also potentially increasing the risk of degradation. Conversely, lower temperatures slow down the reactions, impacting charging times and potentially affecting the overall capacity of the battery.

The ideal operating temperature range for lithium-ion batteries typically falls between 15°C and 25°C.

Impact of Extreme Temperatures

Extreme temperatures, both high and low, can significantly impact battery performance. High temperatures can lead to accelerated degradation of the battery’s components, potentially reducing its overall capacity and shortening its lifespan. Similarly, very low temperatures can reduce the battery’s ability to discharge efficiently, leading to a decrease in the usable range of the vehicle. This reduction in capacity at low temperatures can be substantial, sometimes resulting in a noticeable reduction in the driving range.

Mitigation Strategies by Manufacturers

Manufacturers employ various strategies to mitigate the negative effects of temperature fluctuations on battery performance. These strategies encompass a range of approaches, from thermal management systems to battery chemistry optimization. Thermal management systems are critical for maintaining optimal temperatures within the battery pack, using a combination of active cooling (fans, pumps) and passive methods (insulation). The design of the battery pack itself also plays a significant role, with the choice of materials and their arrangement influencing how effectively heat is managed.

Lithium-ion Battery Performance at Varying Temperatures

| Temperature (°C) | Estimated Capacity (%) | Charging Time (Estimated) |

|---|---|---|

| 0 | 85-90 | Slightly longer |

| 25 | 100 | Optimal |

| 40 | 95-98 | Potentially faster, but with increased degradation risk |

The table above provides a general comparison of lithium-ion battery performance at different temperatures. Note that these are estimations, and actual performance may vary depending on the specific battery chemistry and vehicle design. Factors such as the battery’s cooling system, driving conditions, and the specific battery model can influence these numbers. The charging time estimations also depend on the charging infrastructure and the current being drawn.

Effect of Humidity on Battery and Motor Performance

Source: co.uk

High humidity levels can significantly impact the performance and longevity of electric vehicle (EV) components. Understanding these effects is crucial for optimizing EV operation and ensuring reliable performance in various climates. Moisture can lead to degradation of battery components, affect motor efficiency, and even impact the overall electrical conductivity within the vehicle.Humidity, while not as detrimental as extreme temperatures, can still introduce challenges to the delicate internal workings of EVs.

The presence of water vapor can lead to corrosion, insulation issues, and reduced efficiency across critical components. This effect needs careful consideration in the design and maintenance of EVs to ensure optimal performance in diverse environments.

Role of Humidity in Battery Component Degradation

Humidity accelerates the degradation of battery components by increasing the risk of corrosion. Electrochemical reactions within the battery are sensitive to moisture, and elevated humidity can accelerate these reactions, leading to reduced capacity and lifespan. Water molecules can penetrate battery separators and react with the active materials, leading to the formation of corrosive byproducts that hinder performance. This is particularly problematic for lithium-ion batteries, which are sensitive to moisture and prone to degradation when exposed to high humidity levels.

Impact of Humidity on Electric Motor Efficiency

Humidity can impact the efficiency of electric motors in several ways. Moisture can reduce the insulation resistance of motor windings, leading to increased energy loss due to leakage currents. This can cause a decrease in overall motor performance and potentially lead to overheating issues. Moreover, moisture can cause a build-up of deposits on the motor components, further decreasing efficiency and potentially causing operational failures.

Moisture’s Influence on Electrical Conductivity

Moisture affects the electrical conductivity of various components within an EV. Water acts as a conductor, and its presence can lead to unintended current paths, reducing the overall efficiency of the electrical system. This is particularly problematic in areas with high humidity, where moisture can seep into electrical connections and cause corrosion. The presence of moisture can also alter the electrical conductivity of insulation materials, potentially compromising the integrity of the electrical system.

Susceptibility of EV Components to Humidity

Understanding the varying susceptibility of different EV components to humidity is essential for preventive maintenance.

| Component Type | Susceptibility to Humidity | Potential Impacts |

|---|---|---|

| Batteries | High | Reduced capacity, shortened lifespan, potential for thermal runaway |

| Electric Motors | Medium | Reduced efficiency, increased energy loss, potential for overheating |

| Wiring Harness | Medium-High | Corrosion, short circuits, reduced electrical conductivity |

| Control Units | Low | Moisture can impact internal components, potentially causing malfunctions |

| Sensors | Low-Medium | Moisture can affect sensor accuracy and reliability |

Influence of Precipitation on Electric Car Systems

Precipitation, in the form of rain and snow, can significantly impact the performance and longevity of electric vehicles. The intricate electrical systems within these cars are vulnerable to water ingress, potentially leading to short circuits and other malfunctions. Understanding the ways precipitation affects electric car systems is crucial for maintaining their reliability and safety.

Water Ingress and Electrical Malfunctions

Water ingress, the entry of water into electrical components, is a significant concern. Rain and snow can penetrate seals and gaskets, potentially reaching sensitive electronic components. This can result in short circuits, leading to electrical malfunctions, system failures, and even potential fire hazards. The conductive nature of water facilitates the flow of current through unintended pathways, causing damage to the electrical system.

This can affect the battery, motor controllers, and other critical components, potentially leading to a loss of power or complete system failure.

Sealing and Waterproofing Techniques

Manufacturers employ various sealing and waterproofing techniques to mitigate the effects of precipitation. High-quality seals, such as gaskets and rubber seals, are strategically placed around electrical connectors and components to prevent water penetration. These seals are designed with specialized materials and manufacturing processes to resist water intrusion. Advanced materials, like water-resistant plastics and polymers, are used in the construction of enclosures and housings to protect internal components.

Furthermore, rigorous quality control measures are implemented during the manufacturing process to ensure the integrity of these seals and their effectiveness in preventing water damage.

Protection Measures for Electrical Components

Electric vehicle systems are designed with protective measures to safeguard against moisture damage. These measures are crucial for maintaining the vehicle’s functionality and safety in various weather conditions.

| Component | Protection Measures |

|---|---|

| Battery Pack | Water-resistant enclosures, sealed connectors, and redundant safety systems to prevent short circuits and overheating due to water ingress. |

| Motor Controllers | Sealed housings and robust electrical components to withstand water exposure. High-quality insulation is critical to prevent short circuits. |

| Power Electronics | Water-resistant enclosures, careful component placement, and high-quality insulation to prevent electrical malfunction. |

| Wiring Harness | Water-resistant sheathing and connectors to prevent water damage and short circuits. Regular maintenance and inspections can also help to identify and address potential issues. |

| Sensors | Water-resistant casings and specialized materials to prevent corrosion and malfunction. Careful placement to avoid direct water exposure is also crucial. |

Wind Resistance and Aerodynamics: How Weather Affects Electric Car Performance

Wind resistance significantly impacts the range and efficiency of electric vehicles, especially in varying weather conditions. Factors like wind speed and direction, as well as the vehicle’s aerodynamic design, play a crucial role in determining energy consumption. This section delves into the intricate relationship between wind resistance, aerodynamics, and electric vehicle performance.Aerodynamic design directly influences an electric vehicle’s efficiency and range.

Streamlined shapes and low drag coefficients are key to minimizing the energy required to overcome air resistance. Modern electric vehicles often feature sophisticated designs incorporating elements like spoilers, underbody panels, and optimized wheel designs to minimize air resistance and enhance performance in different weather conditions.

Impact of Wind Resistance on Electric Vehicle Range

Wind resistance is a major factor affecting the range of electric vehicles. Stronger winds increase the force acting against the vehicle, requiring more energy to maintain speed. This effect is more pronounced at higher speeds. For example, a 20 mph headwind will significantly reduce the range of an electric vehicle compared to driving in calm conditions. Conversely, tailwinds can extend the range by reducing the resistance the vehicle faces.

Aerodynamic Design and Weather Conditions

The aerodynamic design of an electric vehicle significantly influences its efficiency, particularly in various weather conditions. Rain and wind can affect airflow around the vehicle, impacting its aerodynamic performance. For example, heavy rain can create a layer of water around the vehicle, increasing drag. Similarly, strong winds can alter the airflow pattern, causing turbulent conditions and impacting the vehicle’s efficiency.

Comparison of Aerodynamic Drag Coefficients

| Electric Car Model | Aerodynamic Drag Coefficient (Cd)

|

Aerodynamic Drag Coefficient (Cd)

|

Aerodynamic Drag Coefficient (Cd)

|

|---|---|---|---|

| Model A | 0.25 | 0.28 | 0.30 |

| Model B | 0.28 | 0.32 | 0.35 |

| Model C | 0.22 | 0.25 | 0.28 |

Note: Values are illustrative and based on estimated conditions. Actual values can vary based on specific driving conditions and vehicle configurations.

Influence of Rain and Wind on Airflow

Rain and wind significantly alter the airflow around an electric vehicle. Rain creates a layer of water on the vehicle’s surface, increasing drag. This effect is more pronounced with higher rain intensity and larger surface areas exposed to the rain. Wind can cause turbulent airflow, impacting the vehicle’s efficiency and affecting the stability of the vehicle, particularly at higher speeds.

The shape of the vehicle plays a crucial role in how it interacts with the airflow. A streamlined shape reduces the impact of rain and wind on the vehicle’s performance.

Tire Performance in Different Weather Conditions

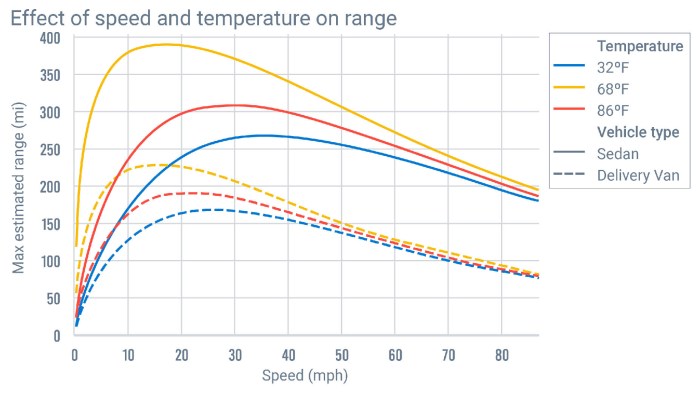

Source: geotab.com

Electric vehicle performance is intricately linked to tire characteristics. Tire grip and traction directly influence acceleration, braking, and overall handling, all of which are significantly affected by the prevailing weather conditions. Understanding how tires react to various weather patterns is crucial for safe and efficient electric vehicle operation.

Impact of Snow and Ice on Tire Performance

Tire performance degrades substantially in snowy and icy conditions. The reduced contact between the tire and the road surface leads to a significant decrease in grip and traction. This effect is further exacerbated by the reduced friction caused by the presence of ice. In such conditions, electric vehicles require specialized tires to maintain adequate traction and prevent loss of control.

The inherent properties of the tire material and its tread design play a critical role in determining the level of grip and traction in winter conditions.

Impact of Rain on Tire Performance

Rainfall significantly affects tire performance. The presence of water on the road surface reduces the friction between the tire and the road, leading to a decrease in traction and grip. This effect is particularly pronounced with higher intensity rainfall. Tire tread patterns are designed to effectively channel water away from the contact patch, maximizing contact with the road surface and maintaining traction.

The ability of the tire to disperse water is a key factor in its performance in wet conditions.

Impact of Different Tire Types

Various tire types are engineered for specific weather conditions. Summer tires, designed for optimal performance in dry conditions, often exhibit poor handling and traction in wet conditions. Winter tires, on the other hand, are optimized for low temperatures and snowy/icy conditions, offering improved grip and traction. All-season tires represent a compromise, offering acceptable performance in most weather conditions, but may not match the performance of specialized tires in extreme situations.

The choice of tire type is crucial for maintaining vehicle stability and control in various weather conditions.

Comparison of Tire Performance in Different Conditions

| Tire Type | Wet Conditions | Snowy Conditions | Icy Conditions |

|---|---|---|---|

| Summer Tires | Poor grip and traction due to reduced friction; hydroplaning risk | Very poor grip and traction; low stability | Very poor grip and traction; significant risk of loss of control |

| Winter Tires | Good grip and traction, although not as good as all-season tires in light rain | Excellent grip and traction, providing enhanced stability | Excellent grip and traction, significantly reducing the risk of skidding |

| All-Season Tires | Good grip and traction, but not as good as summer or winter tires in extreme conditions | Acceptable grip and traction, but not as good as winter tires | Acceptable grip and traction, but not as good as winter tires |

The table above summarizes the comparative performance of different tire types in various weather conditions. It highlights the importance of selecting the appropriate tire type for specific weather patterns to ensure optimal vehicle handling and stability. Consideration of these factors is critical for maintaining safety and control in different weather scenarios.

Charging Infrastructure and Weather Resilience

Electric vehicle charging infrastructure plays a crucial role in the widespread adoption of EVs. The reliability and efficiency of these stations are significantly impacted by weather conditions. Extreme temperatures, precipitation, and high winds can all affect the performance and safety of charging equipment. Understanding these impacts is essential for designing resilient and effective charging networks.

Influence of Temperature on Charging Station Performance

Temperature fluctuations directly affect the performance of charging equipment. High temperatures can lead to increased heat generation within the charging station components, potentially impacting the efficiency and lifespan of the equipment. Conversely, extreme cold can cause issues like reduced conductivity in wiring and increased energy consumption during charging. These factors necessitate careful consideration in the design of charging stations for various climates.

For example, specialized cooling systems may be necessary in regions prone to high temperatures to prevent overheating.

Design Considerations for Charging Stations in Different Climates

Several design considerations are crucial for ensuring the resilience of charging stations in diverse climates. These considerations encompass the materials used, the placement of the stations, and the incorporation of weather-resistant features. The choice of materials should prioritize durability and resistance to the elements. For example, using weather-resistant enclosures and materials can protect sensitive components from moisture, wind, and extreme temperatures.

The location of charging stations also plays a vital role. Placement in areas sheltered from strong winds and heavy precipitation is crucial for maintaining functionality.

Examples of Weather-Resilient Charging Infrastructure, How weather affects electric car performance

Several examples showcase the design of charging infrastructure that is resilient to extreme weather events. These stations often employ specialized components to withstand harsh conditions. For instance, many modern charging stations are equipped with enclosures made of high-strength materials, designed to resist high winds and potentially falling debris. Further, some charging stations are built with redundancy and backup systems to ensure operation even during power outages or severe weather events.

For instance, a station might use multiple power sources to maintain charging capability during a power outage.

Impact of Precipitation on Charging Stations

Precipitation, including rain, snow, and hail, can pose significant challenges to the operation of charging stations. Moisture can lead to electrical short circuits, corrosion of components, and reduced efficiency. Consequently, proper sealing and drainage systems are essential to protect the equipment from water damage. For instance, charging stations located in areas with high rainfall may require robust waterproofing to prevent damage.

The use of appropriate grounding systems can also help mitigate the risks associated with lightning strikes.

Driver Behavior and Weather Impacts

Drivers of electric vehicles (EVs) adapt their driving habits in response to changing weather conditions, impacting overall performance and safety. These adjustments, often subtle, can significantly affect range, charging needs, and the vehicle’s overall responsiveness. Understanding these adaptations is crucial for maximizing EV performance and safety in various weather scenarios.

Adjustments in Driving Style

Drivers instinctively alter their driving styles to account for varying weather conditions. For example, in icy or snowy conditions, drivers will likely reduce speed and increase following distance to avoid skidding or losing control. Conversely, in ideal weather conditions, drivers might accelerate more aggressively and maintain shorter distances between vehicles. These modifications are a natural response to perceived hazards and maintain safety.

Impact on Braking Distances and Reaction Times

Weather conditions directly influence braking distances and reaction times. Wet roads significantly increase stopping distances compared to dry surfaces. This is because the reduced friction between tires and the road surface leads to a longer braking distance. Similarly, adverse weather conditions can affect reaction time, as drivers may take longer to process visual cues, leading to a longer reaction time.

For example, heavy rain or snow can impair visibility, necessitating a longer response time.

Relationship Between Driver Experience and Weather Conditions

Driver experience plays a crucial role in adapting to various weather conditions while driving an EV. Experienced drivers are more adept at anticipating changes in weather patterns and adjusting their driving style accordingly. They are better equipped to handle unexpected situations, like sudden changes in road conditions, due to their accumulated knowledge and understanding of the vehicle’s handling characteristics in different weather conditions.

For instance, a driver with experience in winter driving will be more prepared to navigate icy roads, reducing the risk of accidents. Conversely, less experienced drivers may require more time to adapt to unfamiliar weather conditions, potentially impacting their ability to maintain safe driving practices.

Epilogue

In conclusion, the interplay between weather and electric car performance is complex and multifaceted. Factors ranging from battery chemistry and motor efficiency to tire performance and charging infrastructure all play a critical role. Understanding these intricacies is essential for maximizing electric vehicle performance and range, especially in different climates and conditions. Ultimately, a comprehensive understanding of these factors enables informed decisions about vehicle selection, maintenance, and driving strategies, ensuring optimal performance regardless of the weather.

Post Comment