Future Of Electric Vehicle Batteries

Future of electric vehicle batteries, the narrative explores the exciting innovations and challenges shaping the future of electric vehicles. From groundbreaking battery materials to sophisticated charging infrastructure, this comprehensive overview delves into the multifaceted aspects driving the evolution of electric mobility.

The discussion examines the key elements of battery technology, including materials science, manufacturing processes, performance optimization, safety considerations, and charging infrastructure. We’ll analyze the current state of the art and project future trends, ultimately aiming to provide a holistic understanding of the evolving landscape surrounding electric vehicle batteries.

Battery Materials and Chemistry

The future of electric vehicles (EVs) hinges significantly on advancements in battery technology. Current lithium-ion batteries, while dominant, face limitations in terms of energy density, lifespan, and safety. Emerging chemistries and materials are crucial to unlocking greater performance and sustainability in EVs, pushing toward a more sustainable and efficient transportation system.

Current Battery Materials

Lithium-ion batteries, the prevalent technology in EVs today, employ a combination of lithium metal, a cathode material (often lithium cobalt oxide or nickel-rich compounds), and an electrolyte. Their advantages include high energy density, relatively fast charging rates, and a proven track record. However, challenges remain. Cathode materials like cobalt can be expensive and environmentally problematic to source. The use of flammable organic electrolytes contributes to safety concerns, requiring sophisticated battery management systems.

Furthermore, the lifespan of lithium-ion batteries is affected by factors like temperature fluctuations and charging cycles, leading to reduced performance over time.

Emerging Battery Chemistries

Solid-state batteries represent a promising advancement. These batteries replace the liquid or gel electrolyte with a solid material, which significantly enhances safety and potentially boosts energy density. The solid electrolyte offers improved thermal stability and reduces the risk of short circuits or thermal runaway. Solid-state batteries are still under development, but early prototypes show potential for higher energy densities and longer lifespans compared to lithium-ion.

One significant challenge lies in the cost-effectiveness of producing solid electrolytes with the necessary conductivity and stability.

Environmental Impact of Battery Materials

The environmental footprint of battery production extends beyond the raw materials. Manufacturing processes, including mining, refining, and assembly, generate significant greenhouse gas emissions and contribute to environmental pollution. The extraction of lithium, nickel, and cobalt often involves environmentally damaging practices, such as water contamination and habitat destruction. Careful consideration of the entire lifecycle—from mining to disposal—is essential for a truly sustainable battery technology.

Improving Sustainability of Battery Production

Strategies to improve the sustainability of battery production include exploring alternative materials, adopting more sustainable mining practices, and implementing recycling programs. Researchers are investigating alternative cathode materials with reduced environmental impact, such as manganese-based or silicon-based compounds. Responsible mining practices, including water conservation and waste management, are crucial to minimize environmental damage. Implementing robust battery recycling programs is vital to recover valuable materials and reduce the need for new extraction.

Comparison of Battery Types

| Battery Type | Cost | Lifespan (cycles) | Charging Time | Safety |

|---|---|---|---|---|

| Lithium-ion | Moderate | 500-1000 | Fast | Moderate (requires sophisticated management systems) |

| Solid-state | High (currently) | >1000 (projected) | Fast (projected) | High (due to solid electrolyte) |

Note: Cost figures are approximate and vary based on specific materials and production methods. Lifespan and charging times are projections and can vary depending on design and operating conditions.

Battery Manufacturing and Supply Chain

The global shift towards electric vehicles (EVs) necessitates a robust and sustainable supply chain for battery materials. The current landscape, however, presents challenges in terms of material sourcing, manufacturing capacity, and geographical distribution. Addressing these issues is crucial for ensuring a smooth transition to a future powered by electric vehicles.The current battery supply chain is heavily concentrated in a few regions, creating vulnerabilities and dependence on specific nations or regions.

This concentration raises concerns about potential disruptions to the flow of materials and the resultant impact on EV production timelines and costs. Diversification and localization of production are key strategies to mitigate these risks and ensure long-term sustainability.

Current Global Supply Chain for Battery Materials

The current global supply chain for battery materials, primarily lithium, cobalt, nickel, and manganese, is largely concentrated in specific regions. China, for instance, dominates the production of several key battery components, leading to significant reliance on this single source. This concentration presents risks related to geopolitical instability, trade disputes, and supply disruptions. Alternative sources and diversification of production are therefore critical to mitigate these risks.

Challenges and Opportunities in Securing Stable and Sustainable Battery Material Supplies

Securing a stable and sustainable supply of battery materials involves addressing several challenges. These include fluctuating commodity prices, environmental concerns related to mining practices, and geopolitical factors that influence material availability. Opportunities exist in developing sustainable mining practices, exploring alternative battery chemistries, and investing in recycling infrastructure.

Strategies to Mitigate Risks in the Battery Supply Chain

Mitigating risks in the battery supply chain requires a multi-pronged approach. Diversifying sourcing regions for battery materials is essential, along with establishing robust partnerships with suppliers in various countries. Developing robust supply chain management systems and investing in advanced manufacturing technologies can enhance resilience and efficiency. Further, building strategic partnerships with countries possessing significant mineral resources can promote stability.

Innovative Approaches to Localize Battery Production

Localizing battery production is vital for reducing reliance on global supply chains and promoting economic development in various regions. Governments can incentivize investment in battery manufacturing facilities by offering tax breaks, grants, and other support. Collaborative efforts between research institutions, industry players, and government agencies can facilitate the development of new battery technologies and manufacturing processes. Furthermore, promoting the development of local supply chains for critical materials can create a closed-loop system.

Geographic Distribution of Battery Production Facilities and Capacities

| Country | Location | Capacity (GWh/year) |

|---|---|---|

| China | Various locations | >100 |

| South Korea | Various locations | >50 |

| Japan | Various locations | >30 |

| United States | Various locations | ~20 |

| Europe | Various locations | ~20 |

| Other Countries | Various locations | <20 |

Note

Capacities are approximate and can vary significantly based on specific facilities and production cycles. The table represents a snapshot of the current situation and is subject to change as new facilities are constructed and existing ones are expanded. It also doesn’t account for capacity in countries currently experiencing rapid growth in the EV sector.*

Battery Performance and Durability

Source: co.uk

The performance and longevity of EV batteries are crucial for widespread adoption. Factors influencing these characteristics, from operational conditions to manufacturing processes, directly impact consumer trust and the overall viability of electric vehicles. Optimizing these aspects is essential for ensuring long-term satisfaction and minimizing environmental impact.

Factors Affecting Battery Performance

Battery performance in EVs is profoundly affected by several key elements. Temperature fluctuations, for instance, significantly impact electrochemical reactions within the battery, leading to variations in capacity and efficiency. Extreme temperatures, both high and low, can cause degradation and reduced performance. Charge-discharge cycles, representing the number of times a battery is fully charged and discharged, are another critical factor.

Excessive or rapid cycling can accelerate battery aging. Usage patterns, such as driving habits and the frequency of high-power acceleration, also influence battery performance. Frequent acceleration, braking, and high-power use increase the load on the battery and thus its wear.

Strategies for Optimizing Battery Performance Throughout the Vehicle’s Lifespan

Several strategies can be implemented to optimize battery performance throughout the vehicle’s lifespan. Proactive battery management systems (BMS) are paramount, adjusting charging and discharging rates based on real-time conditions and the battery’s state of health. Regular maintenance, including temperature monitoring and cleaning, is essential for preventing premature degradation. Software updates and algorithms are constantly evolving to optimize charging and discharging cycles, adjusting to various driving conditions.

The development of sophisticated algorithms enables the system to adapt to different driving patterns and charging needs, maximizing battery efficiency. Furthermore, promoting consistent driving patterns, avoiding excessive rapid acceleration, and maintaining consistent charging habits can contribute to extended battery life.

Technologies to Enhance Battery Durability and Lifespan

Several technologies are being developed to enhance battery durability and lifespan. Advanced materials, such as lithium-nickel-cobalt-aluminum oxide (NCA) or lithium-nickel-manganese-cobalt (NMC) cathodes, are being researched to improve energy density and cycle life. Thermal management systems are crucial for regulating battery temperature, preventing thermal runaway and maintaining optimal performance in various operating conditions. These systems effectively dissipate heat generated during charging and discharging, extending battery life.

Advanced battery chemistries are continually evolving, with researchers investigating solid-state batteries as a potential future solution. These are expected to provide enhanced safety, higher energy density, and longer lifespan compared to current lithium-ion batteries.

Key Metrics for Evaluating Battery Durability and Lifespan

Several key metrics are used to evaluate battery durability and lifespan. Capacity retention, measured as the percentage of initial capacity retained after a specific number of charge-discharge cycles, is a crucial indicator. Cycle life, representing the number of complete charge-discharge cycles the battery can endure before its capacity drops below a certain threshold, is another important metric. State of health (SOH) assessment evaluates the current performance of the battery relative to its initial capacity.

This provides a comprehensive understanding of the battery’s condition and its remaining lifespan. Battery degradation rates, quantified over time, allow for predictions about the future performance of the battery and enable the development of improved battery management strategies.

Battery Management Systems Comparison

| Battery Management System (BMS) Type | Impact on Battery Performance | Strengths | Weaknesses |

|---|---|---|---|

| Traditional BMS | Adequate performance in basic applications. | Cost-effective. | Limited adaptability to complex driving conditions. |

| Advanced BMS with Adaptive Algorithms | Optimized performance in diverse conditions. | Enhanced efficiency, extended lifespan. | Higher development and implementation costs. |

| Predictive Maintenance BMS | Proactive management of battery health. | Minimizes unplanned battery failures. | Requires sophisticated data analysis. |

This table highlights the varying impact of different BMS types on battery performance. The choice of BMS directly influences the battery’s lifespan and efficiency.

Battery Safety and Reliability

Electric vehicle (EV) batteries, while offering significant environmental and economic benefits, pose unique safety challenges. Ensuring the reliability and safety of these systems is paramount to fostering widespread EV adoption. Understanding the potential hazards, implementing robust safety measures, and rigorously testing battery performance are crucial to minimizing risks and building public trust.

Safety Concerns Associated with EV Batteries

EV batteries, typically using lithium-ion chemistry, contain highly reactive materials. These materials, if mishandled or subjected to extreme conditions, can undergo thermal runaway, leading to fires and explosions. Factors contributing to these risks include manufacturing defects, internal short circuits, external impacts, and thermal abuse. Understanding these potential failure points is vital for mitigating the associated risks.

Strategies to Enhance Battery Safety and Prevent Potential Hazards

Several strategies are employed to mitigate risks associated with EV batteries. These include advanced battery designs incorporating thermal management systems, robust enclosure designs, and sophisticated safety features like thermal sensors, battery management systems (BMS), and active cooling mechanisms. Safety features are integral components, safeguarding against potential hazards, preventing catastrophic events. Materials with improved thermal stability and enhanced fire resistance are crucial in the development of safer battery cells.

Testing Methodologies for Assessing Battery Safety

Rigorous testing protocols are employed to evaluate battery safety characteristics. These protocols include thermal runaway tests, short-circuit tests, impact tests, and abuse tests to simulate real-world conditions. These tests are crucial in identifying potential weaknesses and refining designs for enhanced safety. Accelerated aging tests help to anticipate the battery’s performance over its lifespan, while safety assessments under various environmental conditions ensure suitability for diverse climates.

Regulations and Standards Governing Battery Safety in Electric Vehicles

Stringent regulations and safety standards govern the design, manufacture, and use of EV batteries. These regulations are designed to ensure that EV batteries meet specific safety requirements and minimize the risk of incidents. International organizations and individual countries have established standards to safeguard consumer safety and protect the environment. These standards address the battery’s ability to withstand various hazards.

Compliance with these regulations is essential for the certification and market introduction of EV batteries.

Potential Battery Failure Modes and Mitigation Strategies

| Potential Failure Mode | Mitigation Strategy |

|---|---|

| Thermal Runaway | Advanced thermal management systems, robust cell designs, and effective safety interlocks |

| Internal Short Circuit | Improved cell manufacturing processes, enhanced cell design, and advanced BMS algorithms |

| External Impact | Reinforced battery enclosures, structural integrity testing, and advanced crash safety systems |

| Overcharging/Overdischarging | Sophisticated battery management systems (BMS) with advanced monitoring and control algorithms |

| Electrolyte Leakage | Improved electrolyte design and sealing technologies, rigorous quality control |

Charging Infrastructure and Energy Management

The widespread adoption of electric vehicles (EVs) hinges critically on the availability and reliability of a robust charging infrastructure. Adequate charging options are crucial for addressing consumer concerns about range anxiety and charging convenience, thereby fostering broader EV market penetration. The success of EVs depends on overcoming this critical barrier to entry.The evolution of EV charging infrastructure necessitates a thoughtful approach encompassing diverse charging technologies, station designs, and strategic planning for various locations.

This involves a complex interplay of technological advancements, logistical considerations, and governmental policies, all aimed at creating a seamless charging experience for EV owners.

Impact of Charging Infrastructure on EV Adoption, Future of electric vehicle batteries

The presence of convenient and readily accessible charging stations significantly impacts consumer confidence in EVs. The absence of adequate charging infrastructure can deter potential EV buyers and limit the overall market growth. Sufficient charging options, coupled with rapid charging capabilities, are pivotal for reducing range anxiety and promoting widespread EV adoption. A strong charging network allows for longer trips and greater freedom in travel, mimicking the convenience of gasoline-powered vehicles.

This is especially crucial for long-distance travel and in areas with limited charging options. The convenience and reliability of the charging infrastructure are key determinants of customer satisfaction and market growth.

Charging Technologies

Various charging technologies cater to different needs and driving scenarios. Level 1 charging, utilizing standard household outlets, is suitable for overnight charging and is generally slower. Level 2 charging, employing specialized charging stations, offers a faster charging rate and is common in public areas. Level 3 or DC fast charging provides significantly faster charging capabilities, crucial for long-distance travel, but these stations are typically located in strategically placed areas, often on highways or at major transportation hubs.

Each charging technology has its own advantages and disadvantages, catering to different needs and circumstances.

Charging Station Designs

Charging station designs must be tailored to the specific location and intended use. Station placement should be optimized for accessibility and convenience. Consideration of aesthetic factors is crucial for integrating charging stations seamlessly into the environment. Public charging stations might incorporate features like public restrooms and waiting areas, providing a comfortable experience for users. Conversely, charging stations in residential areas might emphasize user privacy and security.

Comparison of Charging Station Types

| Charging Station Type | Location | Charging Speed | Cost | Accessibility |

|---|---|---|---|---|

| Home Charging | Residential | Slow (Overnight) | Low | High |

| Public Charging (Level 2) | Malls, shopping centers, public parking | Moderate | Moderate | Moderate |

| Public Charging (DC Fast Charging) | Highways, major transportation hubs | Fast | High (potentially) | Moderate |

This table highlights the key characteristics of different charging station types, offering a concise comparison based on location, charging speed, cost, and accessibility. Different charging stations are designed to meet varying needs, catering to different driving scenarios and user preferences.

Future Trends and Research Directions: Future Of Electric Vehicle Batteries

The future of electric vehicle batteries hinges on innovative research and development. Advancements in battery materials, manufacturing, and performance are crucial for broader adoption and continued progress in the electric vehicle sector. This section explores emerging research areas, potential breakthroughs, and the broader implications of these advancements.

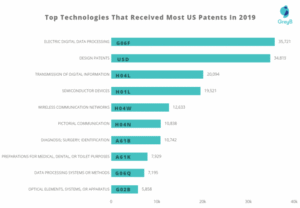

Emerging Research Areas in Battery Technology

Research efforts are actively exploring novel battery chemistries, focusing on improved energy density, faster charging rates, and enhanced safety. Solid-state batteries, a promising area, offer the potential for significantly higher energy density and improved safety compared to traditional lithium-ion batteries. Other promising areas include next-generation lithium-ion battery chemistries, including those utilizing different anode and cathode materials, and the development of advanced battery management systems (BMS).

Potential Breakthroughs in Battery Technology

Several breakthroughs are anticipated within the next 5-10 years. Improvements in solid-state battery technology are expected to lead to greater energy density and improved safety, potentially revolutionizing EV performance. Faster charging times are another crucial area, with advancements in battery chemistries and charging infrastructure potentially enabling more convenient and efficient charging experiences. Furthermore, advancements in battery management systems are expected to optimize battery performance and longevity.

For instance, the development of self-healing battery technologies is also a promising research area that could enhance battery lifespan.

Innovative Applications of Battery Technology Beyond Electric Vehicles

Battery technology is not confined to EVs. Potential applications extend to grid-scale energy storage, portable electronics, and even aerospace. The development of advanced battery technologies for grid-scale energy storage can help stabilize the electricity grid and integrate renewable energy sources more effectively. This will contribute to greater sustainability and grid reliability. Similarly, the use of batteries in portable electronics is expected to continue to increase, with a focus on improving energy density and charging speeds.

Potential Collaborations Between Industry and Academia

Effective collaboration between industry and academia is crucial for accelerating battery research and development. Research institutions can contribute their expertise in materials science, chemistry, and engineering, while companies can provide real-world insights and funding for specific projects. Joint research centers and collaborative projects can facilitate the exchange of knowledge and resources, leading to faster breakthroughs. Examples include the development of joint laboratories and research facilities, as well as the creation of targeted research programs.

Economic and Societal Implications of Advancements in Battery Technology

Advancements in battery technology have significant economic and societal implications. The growth of the EV industry and related sectors will create new jobs and boost economic activity. Lower energy costs for consumers, reduced reliance on fossil fuels, and a cleaner environment are expected outcomes. For example, the deployment of large-scale energy storage solutions will improve grid stability, potentially reducing the cost of electricity for consumers.

The increased adoption of electric vehicles will contribute to the reduction of air pollution and greenhouse gas emissions, positively impacting public health and the environment.

Final Summary

In conclusion, the future of electric vehicle batteries promises significant advancements, but faces substantial challenges. Overcoming these hurdles through innovation in materials, manufacturing, and infrastructure is critical for widespread adoption of electric vehicles and a sustainable transportation future. The interplay of scientific breakthroughs, industrial strategies, and societal needs will define the success story of this transformative technology.

Post Comment