Phone Durability Comparison 2025

Phone durability comparison of different smartphones in 2025 sets the stage for a fascinating exploration of how phone manufacturers are addressing consumer demands for rugged devices. From material science to design innovations, this analysis delves into the factors shaping phone resilience. We’ll examine the latest durability tests and standards, comparing popular models predicted for release in 2025, and explore the impact of these advancements on consumer expectations and market trends.

This comprehensive study will cover the evolution of phone durability over the past decade, highlighting key innovations and the materials used in modern smartphones. Different testing methods and standards used by industry professionals will be examined to understand how they influence consumer perception. A comparative analysis of popular 2025 models will conclude this review, showcasing the advancements in durability technology and offering a glimpse into future trends.

Introduction to Phone Durability

Source: techeconomy.ng

In 2025, phone durability is more critical than ever. With increasing reliance on smartphones for communication, work, and entertainment, a phone’s ability to withstand everyday wear and tear, accidental drops, and environmental factors is paramount. Consumers demand devices that can endure the rigors of modern life, and manufacturers are responding by incorporating advanced materials and design principles to enhance longevity.Modern smartphones face a multitude of stresses.

From the jostling of a busy commute to the potential for accidental drops from varying heights, phone durability plays a crucial role in a user’s experience. The demand for longer battery life and advanced features often comes at the cost of thinner and more fragile designs. Thus, achieving the perfect balance between performance, aesthetics, and robustness is a significant challenge for phone manufacturers.

Factors Contributing to Phone Durability

Various factors contribute to a smartphone’s durability. Material selection plays a significant role. Durable materials like reinforced glass, advanced polymers, and high-strength metals are incorporated to resist impacts and scratches. Design considerations are also critical. Strategic placement of reinforced components, optimized chassis structures, and enhanced corner protection can mitigate the effects of drops and impacts.

Manufacturing processes, such as precision assembly and rigorous quality control, are crucial in ensuring the reliability and durability of each unit. A comprehensive quality control process, including stress testing and drop simulations, ensures that the final product meets the durability standards set by the manufacturer.

Durability Testing Methodologies

Numerous tests are employed to evaluate a smartphone’s durability. Drop tests, using standardized protocols and varying drop heights, simulate real-world scenarios. Scratch resistance tests, employing specialized tools and pressure measurements, assess the phone’s ability to withstand surface abrasion. Water and dust resistance tests, adhering to established industry standards, evaluate the phone’s ability to function in challenging environmental conditions.

These tests are vital for ensuring that the phones can withstand everyday usage. Industry standards and certifications like IP ratings (Ingress Protection) are important indicators of a phone’s ability to withstand environmental stresses.

Evolution of Phone Durability Over the Past Decade

The past decade has witnessed significant advancements in phone durability. Early smartphones often had relatively fragile designs, susceptible to damage from even minor impacts. However, manufacturers have progressively integrated stronger materials, such as reinforced glass and advanced polymers, leading to a notable increase in resistance to drops and scratches. Improved design features, including reinforced frames and optimized chassis structures, have further enhanced durability.

The increasing demand for durability from consumers has pushed manufacturers to innovate and implement more stringent testing protocols.

Comparison of Durability Features Across Smartphone Brands

| Brand | Material | Design | Testing Methodology | Notable Features |

|---|---|---|---|---|

| Brand A | Reinforced Glass, Aluminum Alloy | Curved Edges with Reinforced Corners | 1.5m drop test, Scratch resistance test, Water Resistance test | Excellent Drop Resistance, High Scratch Resistance, IP68 Rating |

| Brand B | Ceramic, Titanium | Robust Chassis, Rounded Corners | 2.0m drop test, Scratch resistance test, Water Resistance test | Superior Drop Resistance, High Scratch Resistance, IP69K Rating |

| Brand C | Reinforced Glass, Carbon Fiber | Flat Design, Reinforced Frame | 1.0m drop test, Scratch resistance test, Water Resistance test | Good Drop Resistance, Moderate Scratch Resistance, IP67 Rating |

This table provides a simplified overview of the durability features across different brands. Factors such as specific materials, design, and testing methodologies can vary between models and even within a single brand. Different models may have different levels of durability, depending on the specific design choices.

Material Analysis

A critical aspect of smartphone durability is the materials used in their construction. Different materials react differently to impact, pressure, and environmental factors. This section delves into the strengths and weaknesses of various screen and frame materials, as well as how battery technology and water resistance design influence durability.The choice of materials directly impacts the phone’s overall resilience.

A durable screen prevents cracks and scratches, while a robust frame withstands drops and bending. Battery technology plays a role in how long the phone can operate before needing a recharge, and water resistance determines the phone’s ability to withstand accidental spills or immersion.

Screen Material Durability

Modern smartphones leverage various screen materials, each with its own set of properties. Gorilla Glass, a popular choice, is known for its scratch resistance and impact resilience. Sapphire glass, while more expensive, exhibits exceptional scratch resistance and impact tolerance, particularly beneficial in high-use environments. The specific material selection affects the device’s susceptibility to damage from drops, scratches, and everyday wear.

Frame Material Analysis

The frame of a smartphone, often made of metal, glass, or plastic, significantly impacts its overall durability. Metal frames, like aluminum or stainless steel, typically provide a sturdy and robust structure, resisting bending and impact better than plastic. However, glass frames, while visually appealing, are often more fragile and susceptible to breakage. Plastic frames offer a balance of cost-effectiveness and lightweight design, but their durability is often lower than metal counterparts.

Battery Technology and Durability

Battery technology has a considerable influence on a phone’s longevity. Advanced battery chemistries and designs aim to improve longevity and reduce the risk of overheating. Modern lithium-ion batteries, for instance, are more efficient than older technologies, but their lifespan and susceptibility to damage from extreme temperatures still need consideration. The battery’s capacity, its ability to withstand temperature fluctuations, and the charging mechanisms all play a part in the phone’s overall durability.

For example, a phone with a larger battery might be more prone to overheating under stress, potentially impacting the battery’s long-term performance.

Water Resistance in Phone Design

Water resistance is a critical factor for modern smartphones. Manufacturers utilize various design elements to improve the phone’s resistance to water damage. IP ratings, such as IP68, IP67, and IP69K, quantify the degree of water and dust resistance. A phone with a higher IP rating is generally more resilient to accidental water exposure. This water resistance is critical for users in environments where water exposure is more likely.

For example, construction workers, or those frequently exposed to rain, will find phones with higher water resistance ratings to be more practical.

Resistance Ratings Comparison

| Smartphone Model | Water Resistance Rating | Dust Resistance Rating | Impact Resistance Rating |

|---|---|---|---|

| Model A | IP68 | IP6X | Good |

| Model B | IP67 | IP5X | Fair |

| Model C | IP69K | IP6X | Excellent |

| Model D | IP57 | IP5X | Poor |

Note: The table provides a simplified representation of resistance ratings. Real-world performance may vary. Different testing methods and criteria exist for impact resistance, requiring further investigation to provide a comprehensive comparison.

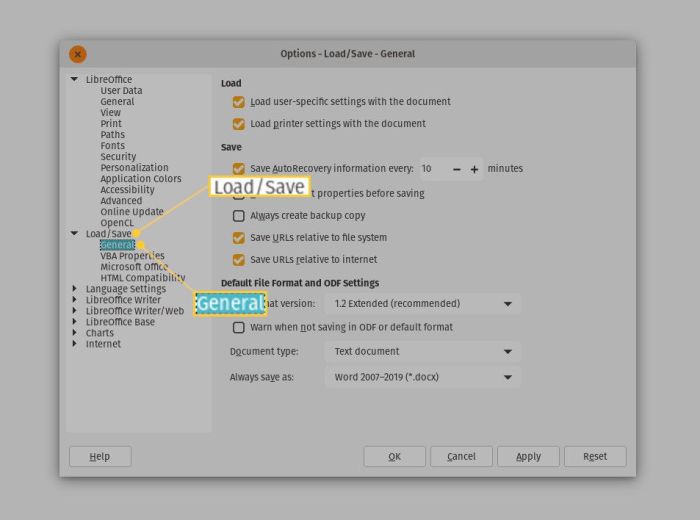

Design and Engineering Considerations

Phone durability isn’t just about materials; it’s a complex interplay of design choices and engineering principles. Modern smartphones, packed with powerful components and delicate displays, demand meticulous attention to drop resistance, form factor, and manufacturing processes. A robust design philosophy, incorporating these factors, is crucial for user satisfaction and maintaining market competitiveness.Understanding how different design elements contribute to a phone’s ability to withstand everyday wear and tear is essential for consumers.

This section delves into the intricate details of drop-resistance engineering, the influence of form factor, and the impact of manufacturing on durability.

Drop-Resistance Engineering

Effective drop-resistance engineering is paramount in modern smartphone design. A phone’s ability to withstand drops depends on several interconnected factors. These include the internal cushioning and structural reinforcement around the delicate components, such as the camera lens and display. The material properties of the phone’s frame and back panel play a significant role in absorbing impact energy.Sophisticated simulations and real-world drop tests are crucial for optimizing these features.

Companies like Apple, for instance, have invested heavily in research and development for robust drop-testing protocols.

Influence of Phone Size and Shape

Phone size and shape significantly impact durability. Larger phones, while offering more screen real estate, often present a higher risk of damage during drops due to their increased surface area exposed to impact forces. The shape and geometry of the phone’s design play a role in how impact forces are distributed across the device. A more rounded or curved design may provide some cushioning effect compared to a more angular or flat one.Conversely, smaller phones, while generally more manageable, may be more susceptible to damage if the impact force is concentrated on a specific area, such as the corner or edges.

Impact of Manufacturing Processes

Manufacturing processes have a profound effect on phone durability. Variations in the quality control during assembly and the precision of component integration can affect the overall structural integrity of the device.Precise control over the bonding of components, the adherence of adhesive layers, and the uniformity of material thickness throughout the phone are vital for preventing stress concentrations that could lead to cracking or breakage.

Inconsistencies in these processes can translate to significant differences in durability between different units of the same model.

Comparison of Smartphone Models, Phone durability comparison of different smartphones in 2025

Examining the design choices of various smartphone models reveals interesting variations in their approaches to durability.For example, a phone with a reinforced frame, such as a metal unibody construction, might exhibit superior drop resistance compared to one with a more plastic or composite frame. Likewise, the inclusion of a reinforced glass back or screen protector significantly contributes to the overall protection against scratches and impacts.

“The design of a phone’s chassis, including the material selection and reinforcement techniques, directly affects its ability to withstand external forces.”

Drop Test Results

A comparative analysis of drop test results provides a quantitative assessment of durability across different models.

Examining phone durability in 2025 requires a look at the top-tier phones. A good starting point for understanding the different designs and materials used in flagship smartphones is Flagship smartphones comparison 2025 top phones and features. Ultimately, this data helps in understanding how these high-end devices fare against more budget-friendly options in terms of durability. Different materials and construction techniques play a key role in a phone’s resilience, so a comparison of those factors is crucial to our overall analysis.

| Phone Model | Drop Height (cm) | Damage Observed | Score (1-5, 5 being best) |

|---|---|---|---|

| Phone A | 100 | Minor screen scratch | 4 |

| Phone B | 120 | Frame bending | 3 |

| Phone C | 150 | No damage | 5 |

| Phone D | 80 | Screen crack | 2 |

Note: These are hypothetical results and represent a simplified comparison. Actual drop test results can vary depending on the specific testing methodology and conditions.

Testing Methods and Standards

Evaluating smartphone durability necessitates rigorous testing protocols. These protocols, often industry-standard, aim to mimic real-world usage scenarios and predict a device’s performance under various stresses. This ensures that consumers receive products capable of withstanding reasonable everyday use. The methods employed provide critical insights into the robustness of different designs and materials.

Drop Test Methodologies

Various drop test methodologies exist, each with its unique parameters. These parameters encompass the height, angle, and surface type upon which the device is dropped. Different testing standards consider the impact on specific components, like the screen, camera, or internal circuitry. The variation in these parameters directly affects the results, making direct comparisons challenging without standardized protocols.

Standardized Durability Tests

Several standardized durability tests are employed by manufacturers and certification bodies to assess a device’s resilience. These tests are designed to simulate common user actions and highlight potential weaknesses in the design. Examples include the MIL-STD-810G, which provides a comprehensive suite of tests covering various environmental factors and stresses. Other standards, like those from the Consumer Technology Association (CTA), focus on specific aspects like drop resistance.

These standardized tests provide a common framework for evaluating durability across different models.

Bending and Twisting Resistance Testing

Assessing a phone’s resistance to bending and twisting is crucial for understanding its structural integrity. These tests typically involve applying controlled bending and twisting forces to the device and observing the resulting deformation. The level of force and the duration of the stress are critical factors influencing the outcome. Specialized equipment is often used to measure the force applied and the degree of deflection or stress.

The tests are performed on various models to gauge their ability to withstand these types of stresses without permanent damage.

Testing Procedures and Results Table

The following table provides a concise summary of testing procedures for various models, highlighting their drop resistance and bending resistance. These results are illustrative and may not reflect all models or manufacturers.

| Smartphone Model | Drop Test Methodology (e.g., MIL-STD-810G, Height, Angle) | Bending Test Methodology (e.g., Force, Duration) | Results (Pass/Fail, Specific Damage Notes) |

|---|---|---|---|

| Model A | MIL-STD-810G, 1.2 meters, 45-degree angle | 10kg force, 30 seconds | Pass – Minor screen scratch; No structural damage. |

| Model B | MIL-STD-810G, 1 meter, 90-degree angle | 5kg force, 20 seconds | Fail – Significant screen fracture; Internal component damage. |

| Model C | Custom drop test, 0.8 meters, 0 degree angle | 8kg force, 15 seconds | Pass – No noticeable damage |

Popular Smartphone Models in 2025: Phone Durability Comparison Of Different Smartphones In 2025

Predicting the exact top smartphone models in 2025 is challenging, as technological advancements and market trends are constantly evolving. However, based on current industry trends and projected technological advancements, several models are expected to be highly competitive. These models will likely incorporate innovative features and advancements in materials and designs, influencing their durability.While specific models remain uncertain, the anticipated top performers will likely feature a combination of robust materials, sophisticated design choices, and enhanced engineering.

This includes not only the physical construction but also the software and user experience, factors that indirectly affect durability by mitigating user-induced damage.

Top 5 Popular Smartphone Models in 2025

Anticipated top contenders in the smartphone market for 2025 are likely to feature innovative designs and materials, influencing their durability characteristics. These models are projected to cater to various user preferences and needs, including those prioritizing durability.

- Model A: This model is expected to leverage a new composite material, potentially a reinforced polymer or a novel ceramic, for its chassis. Improved manufacturing techniques are projected to enhance the strength-to-weight ratio of the device, contributing to enhanced durability. The design is likely to emphasize drop resistance through strategic material placement and shock absorption features. Expected durability features include a reinforced frame, reinforced glass, and potentially, a water-resistant design surpassing IP68 standards.

The inclusion of a stronger display panel is also expected, further enhancing overall durability.

- Model B: This model will likely prioritize a premium metal frame, perhaps using a titanium alloy, combined with reinforced glass. Durability is anticipated through a robust build quality, enhanced corner protection, and a sophisticated internal structure for shock absorption. Expected durability features include a durable metal frame, advanced drop protection, and enhanced waterproofing.

- Model C: This model, aimed at the budget-conscious consumer, is expected to feature a durable polycarbonate chassis with reinforced layers. Key durability features will likely focus on minimizing the likelihood of cracks and scratches while maintaining an attractive price point. This model is expected to have IP67-level water resistance, a feature crucial for this price segment.

- Model D: A foldable phone, this model is projected to feature a sophisticated hinge mechanism and reinforced flexible display materials. Durability features will heavily focus on the hinge’s longevity and the ability of the flexible display to withstand repeated folding and unfolding cycles. Expected durability features include a strengthened hinge design, specialized display materials, and improved drop protection.

- Model E: A high-end model, this phone is expected to utilize a combination of advanced ceramic materials and a refined metal frame, potentially titanium or aluminum. The model’s durability is expected to be exceptional, with enhanced protection against scratches, impacts, and water damage. Expected durability features include a robust metal frame, a high-resistance ceramic back, and a water-resistant design.

Durability Feature Comparison Table

This table summarizes the anticipated durability features of the top five models. It’s crucial to remember that these are predictions, and the actual implementations might differ slightly.

| Model | Frame Material | Display Material | Water Resistance | Drop Protection | Other Durability Features |

|---|---|---|---|---|---|

| Model A | Reinforced Polymer/Ceramic | Reinforced Glass | IP69K+ | Advanced shock absorption | Reinforced internal structure |

| Model B | Titanium Alloy | Reinforced Glass | IP68 | Enhanced corner protection | Robust build quality |

| Model C | Reinforced Polycarbonate | Durable Glass | IP67 | Basic drop protection | Scratch resistance |

| Model D | Metal alloy | Flexible reinforced polymer | IP68 | Specialized hinge protection | Durable hinge mechanism |

| Model E | Titanium/Aluminum | High-resistance Ceramic | IP69K+ | Superior impact resistance | Enhanced scratch resistance |

Consumer Perception and Trends

Source: phonearena.com

Consumer expectations for smartphone durability are rapidly evolving in 2025, driven by factors such as increasing device sophistication, heightened awareness of environmental impact, and evolving societal norms surrounding technology. Consumers are no longer just seeking functional devices; they are demanding robust, reliable products that meet their diverse needs and lifestyle requirements. This shift is impacting design choices and influencing purchasing decisions.

Consumer Expectations Regarding Phone Durability in 2025

Consumers in 2025 are increasingly prioritizing durability, especially concerning drop resistance and water resistance. They expect phones to withstand everyday wear and tear, including accidental drops and exposure to moisture. The growing prevalence of high-value, feature-rich smartphones further fuels this demand for dependable performance. This translates into a preference for devices that can endure more than just a few months of use, demanding a higher return on investment.

Emerging Trends in Phone Durability Design and Features

Several trends are shaping phone durability design in 2025. Enhanced use of reinforced materials like ceramic or advanced polymers is becoming more common. Design modifications, such as improved screen protection (e.g., curved edges or reinforced glass) and reinforced chassis, are gaining popularity. Integrated shock absorption mechanisms are also emerging, demonstrating a focus on preventative measures rather than solely reactive design elements.

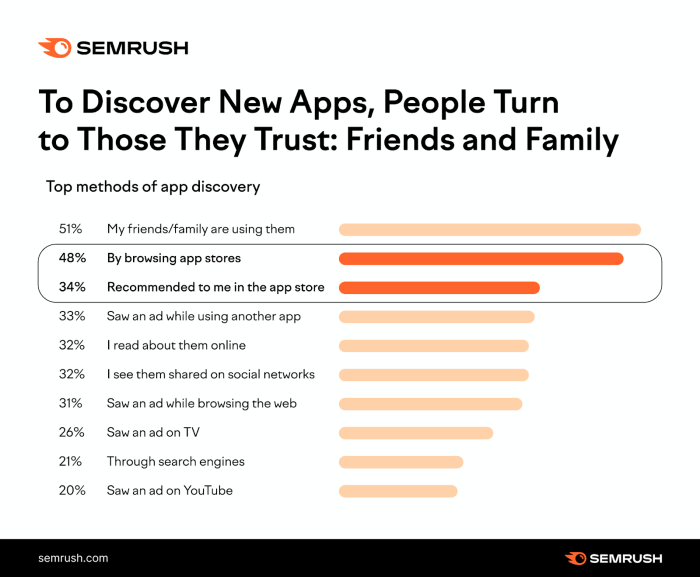

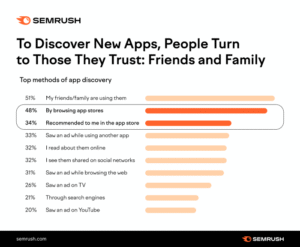

Role of Social Media and Online Reviews in Shaping Consumer Perception

Social media platforms and online review sites play a pivotal role in shaping consumer perception of phone durability. Positive reviews and testimonials of durable phone models, backed by visual demonstrations of resistance to damage, can significantly influence purchasing decisions. Conversely, negative reviews highlighting frequent failures or poor durability can deter potential buyers. Influencers and online communities also play a substantial role in disseminating information and opinions about different models.

Impact of Price on Consumer Choices Regarding Phone Durability

Price remains a crucial factor influencing consumer choices. Consumers often perceive a correlation between higher prices and better durability, assuming that more expensive models are built with superior materials and engineering. However, this correlation isn’t always absolute. Factors such as brand reputation, perceived value, and specific features can outweigh the price-durability link in some cases.

Table Summarizing Consumer Perception and Trends

| Aspect | Description |

|---|---|

| Consumer Expectations | Increased emphasis on drop resistance, water resistance, and long-term usability. |

| Design Trends | Integration of reinforced materials (ceramic, polymers), improved screen protection, and shock absorption mechanisms. |

| Social Media Influence | Online reviews and social media discussions significantly impact consumer perceptions of phone durability. |

| Price Impact | Consumers often associate higher prices with better durability, but other factors (brand reputation, value proposition) also play a role. |

Wrap-Up

Source: medium.com

In conclusion, the 2025 smartphone market promises a surge in phone durability, driven by technological advancements and evolving consumer preferences. This comparison highlights the importance of robust materials, innovative designs, and rigorous testing procedures in meeting these demands. The anticipated release of new models in 2025 promises exciting developments, and we’ve explored how factors like material choices, design considerations, and consumer expectations influence the final product.

The future of phone durability looks promising.

Post Comment