Development Of Touchscreen Technology

Development of touchscreen technology has revolutionized how we interact with devices. From the early, rudimentary prototypes to the sophisticated displays we use today, the journey has been marked by significant advancements in materials, design, and manufacturing processes. This exploration delves into the historical context, technological breakthroughs, and practical applications of touchscreens, examining their impact on various industries and considering future trends.

The evolution of touchscreen technology has been driven by a confluence of factors, including the need for intuitive user interfaces, the growth of mobile computing, and the continuous push for improved display and sensor technologies. Understanding these factors is crucial to grasping the full scope of touchscreen development.

Early Stages of Touchscreen Technology

The development of touchscreen technology, enabling direct interaction with digital displays, has been a fascinating journey. From rudimentary prototypes to sophisticated modern interfaces, the evolution reflects advancements in materials science, electronics, and user experience design. This section delves into the initial stages, examining key inventions, challenges, and the technologies that paved the way for today’s touchscreens.Early touchscreen technology relied on a variety of methods to detect user input.

These early approaches, while often limited in functionality and accuracy, laid the groundwork for the more sophisticated systems used today. Understanding their design and limitations provides context for the ongoing evolution of touchscreen technology.

Historical Overview and Key Inventions

Early touchscreen concepts emerged in the mid-20th century, driven by a desire for more intuitive interaction with computers. Key inventions and milestones helped shape the development of touchscreens. The development of the first practical touchscreens was marked by several key inventions and breakthroughs, with each iteration building upon the previous one. This progression showcases the iterative nature of technological advancement.

Initial Challenges and Limitations

Early touchscreen devices faced numerous challenges. Accuracy and responsiveness were often poor, and the devices were typically bulky and expensive. The early prototypes suffered from limitations in precision and speed, making them less user-friendly compared to modern touchscreens. These initial hurdles hindered widespread adoption, but ultimately contributed to the development of more refined technologies.

Materials and Technologies Used in Early Prototypes

Early touchscreen prototypes employed a variety of materials and technologies. These varied approaches demonstrate the experimentation and exploration in the field during the formative years of touchscreen technology. Understanding the materials used in early prototypes provides insights into the technological limitations and advancements during the initial stages of development.

| Type of Touch Input | Description | Materials | Limitations |

|---|---|---|---|

| Resistive | Two layers of conductive material, separated by a gap. Pressure on the surface creates electrical contact. | Thin films of metal, conductive polymers | Lower accuracy, prone to damage, susceptible to dust and debris, low sensitivity. |

| Capacitive | Detects changes in electrical fields. A conductive layer on the screen and the user’s finger or stylus act as part of a circuit. | Glass, conductive coatings | Requires a conductive object (e.g., finger, stylus), more complex electronics. |

| Infrared | Grid of infrared sensors detects the interruption of an infrared beam when a finger or object touches the screen. | Infrared light sources, photodetectors | Bulky, susceptible to interference, more expensive than resistive or capacitive. |

Comparison of Early Touch Input Methods

The table above compares different types of early touch input methods. Each method had unique characteristics that influenced their applicability and adoption. The table highlights the trade-offs between accuracy, cost, complexity, and user experience. This comparative analysis reveals the diverse approaches taken in the early stages of touchscreen technology.

Technological Advancements

The development of touchscreen technology wasn’t a singular event but a gradual process fueled by concurrent advancements in various fields. Key breakthroughs in display technology, processing power, and sensor technology significantly improved the user experience and broadened the applications of touchscreens. This evolution led to the diverse range of touchscreen devices we see today.

Major Technological Breakthroughs

Several key technological advancements significantly impacted the development of touchscreen technology. These advancements, intertwined and mutually reinforcing, created the conditions for the rapid proliferation of touchscreens in various devices. Improved display technologies, more powerful processors, and sophisticated sensor systems each played a critical role in the progress.

Improvements in Display Technology

Display technology improvements were crucial for touchscreen development. Early displays often suffered from poor resolution, limited color depth, and slow response times, hindering the user experience. The transition to higher resolution, wider color gamuts, and faster response rates, directly benefited touchscreen functionality and user experience. Advances in liquid crystal displays (LCDs), particularly the introduction of active-matrix technology, enabled faster refresh rates and higher contrast ratios, enhancing the overall touch response.

Improvements in Processing Power

The increasing processing power of microprocessors became critical for handling the complex tasks associated with touchscreen interaction. Early touchscreens often relied on relatively simple processors, leading to lag or sluggish responses. The rise of more powerful microcontrollers and integrated circuits allowed for more sophisticated processing of touch input, leading to smoother and more responsive touch interfaces. Real-time processing of touch data became possible, enhancing the overall user experience.

Improvements in Sensor Technology

Sensor technology is the foundation of touch recognition. Early sensors often had limited accuracy or sensitivity. The development of more precise and responsive pressure-sensitive sensors was crucial. The advent of capacitive and resistive touch sensors enabled more accurate and reliable input detection, significantly improving user interaction. The shift from resistive to capacitive touchscreens, for example, resulted in improved accuracy and reduced susceptibility to environmental factors.

Evolution of Capacitive and Resistive Touchscreens

Capacitive and resistive touchscreens represent the two major categories. Resistive touchscreens, utilizing pressure to detect touch, were the first widely adopted technology. However, they suffered from limitations in accuracy and durability. Capacitive touchscreens, detecting changes in electrical fields, eventually surpassed resistive touchscreens in performance and reliability. This transition resulted in more responsive and accurate touch interactions, with capacitive touchscreens being more resistant to environmental factors like dust and moisture.

Touchscreen Display Generations

| Generation | Key Features | Specifications |

|---|---|---|

| First Generation | Early resistive touchscreens; limited accuracy, low resolution; susceptible to environmental factors. | Low resolution, slow response time, limited color depth. |

| Second Generation | Improved resistive touchscreens; slightly enhanced accuracy and response. | Slightly higher resolution, improved response time. |

| Third Generation | Emergence of capacitive touchscreens; higher accuracy and durability. | Increased accuracy, improved durability, higher resolution, wider color gamut. |

| Fourth Generation | Advanced capacitive touchscreens; multi-touch support, pressure sensitivity. | Support for multi-touch input, improved pressure sensitivity, high resolution, high refresh rate. |

Applications and Impact

Touchscreen technology has profoundly impacted various industries, transforming how we interact with devices and accelerating the rise of mobile computing. Its versatility allows for intuitive interfaces, leading to enhanced user experiences and increased efficiency across numerous sectors. From simple mobile phones to sophisticated medical equipment, the adaptability of touchscreen technology is evident in its widespread adoption.The diverse applications of touchscreen technology are not limited to a single industry.

Its adoption has created a paradigm shift in user experience, making interactions more natural and intuitive. This, in turn, has fueled the exponential growth of mobile computing, changing the way we work, play, and learn.

Diverse Applications Across Industries

Touchscreen technology’s adaptability transcends specific industries. Its widespread integration has created innovative solutions and improved efficiency across numerous sectors.

- Consumer Electronics: Smartphones, tablets, and e-readers are ubiquitous examples of touchscreen applications in consumer electronics. The intuitive touch interface significantly enhances user engagement with media consumption, gaming, and productivity tools. This has resulted in increased sales and market share for touchscreen-based devices.

- Healthcare: Touchscreens are increasingly prevalent in medical equipment, from diagnostic tools to surgical robots. Their use streamlines data entry, enhances image analysis, and improves the overall efficiency of medical procedures. For instance, touchscreen interfaces in X-ray machines allow for more precise and rapid analysis of images.

- Automotive Industry: Touchscreen interfaces are transforming the driver experience in automobiles. From infotainment systems to navigation and climate control, these interfaces offer a user-friendly and efficient way to manage various vehicle functions. The integration of touchscreens in cars has increased the perceived value and desirability of modern vehicles.

- Retail: Touchscreens are becoming common in retail settings, enabling interactive displays, self-checkout kiosks, and personalized customer experiences. This facilitates faster transactions, provides more information to customers, and enhances the overall shopping experience.

- Education: Interactive whiteboards and educational tablets are utilizing touchscreen technology to enhance learning experiences. This technology enables interactive lessons, multimedia presentations, and personalized learning paths, leading to more engaging and effective teaching methodologies.

Impact on User Experience and Interaction

Touchscreen technology has revolutionized user interaction with devices. The intuitive nature of touch interfaces has simplified navigation and made tasks more accessible. This shift has significantly improved the user experience, making devices more engaging and user-friendly.The adoption of touchscreen interfaces has reduced the learning curve for users, allowing them to interact with devices more naturally and intuitively. This ease of use is especially pronounced in applications that require frequent input, such as gaming or mobile banking.

Role in the Rise of Mobile Computing, Development of touchscreen technology

Touchscreen technology is a key driver behind the rise of mobile computing. The intuitive interface allows for a more portable and accessible computing experience, making computing power more accessible to users on the go. This has led to an exponential growth in the mobile device market and has dramatically impacted various aspects of daily life.The portability and ease of use of touchscreen devices have made mobile computing a vital part of modern life.

This widespread accessibility has fostered the growth of applications and services tailored to mobile platforms, further enhancing the appeal and usefulness of mobile devices.

Types of Devices Utilizing Touchscreen Technology

The table below provides a categorized overview of devices employing touchscreen technology across different industries.

| Industry | Device Type |

|---|---|

| Consumer Electronics | Smartphones, Tablets, E-readers, Smartwatches |

| Healthcare | Diagnostic Equipment, Surgical Robots, Patient Monitoring Systems |

| Automotive | Infotainment Systems, Navigation Systems, Climate Control Panels |

| Retail | Self-Checkout Kiosks, Interactive Displays, Point-of-Sale Systems |

| Education | Interactive Whiteboards, Educational Tablets, Learning Platforms |

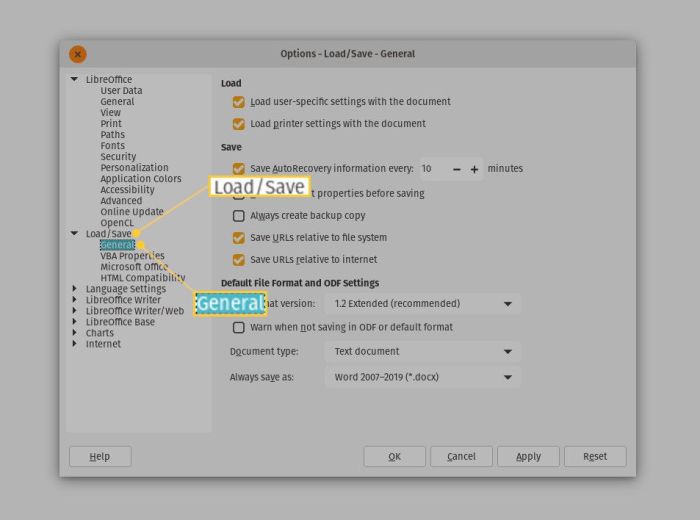

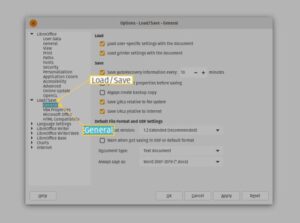

Manufacturing Processes

The production of touchscreen displays involves intricate manufacturing processes, encompassing material preparation, sensor integration, and assembly. Different techniques are employed depending on the specific type of touchscreen and desired performance characteristics. These processes demand precision and meticulous control to ensure the functionality and reliability of the final product.The assembly and integration of touch sensors are crucial steps in touchscreen display manufacturing.

The delicate nature of these components necessitates precise alignment and bonding procedures to prevent malfunction and ensure responsiveness. Sophisticated equipment and specialized expertise are often required to execute these stages.

Material Preparation and Fabrication

The quality of materials significantly impacts the performance and durability of touchscreen displays. High-quality glass substrates, transparent conductive oxides (like indium tin oxide or ITO), and adhesive layers are critical components. These materials undergo meticulous preparation and fabrication to ensure uniformity, purity, and adhesion properties. The thickness and surface smoothness of the glass must meet stringent requirements to guarantee clarity and responsiveness.

Various techniques are employed for glass processing, including chemical etching and thermal tempering, ensuring the required mechanical strength and surface characteristics.

Touch Sensor Integration

The integration of touch sensors is a critical stage in touchscreen display production. Different types of touch sensors are used, each with its own advantages and limitations. Capacitive touch sensors, for example, detect the change in capacitance when a finger or stylus touches the display surface. Resistive touch sensors, on the other hand, rely on the pressure exerted by the input device to generate a signal.

The choice of sensor type often depends on the desired level of sensitivity and precision.

Assembly and Integration of Components

The assembly process involves precise alignment and bonding of various components. This includes aligning the touch sensor layer with the display panel, bonding them using adhesives, and ensuring the integrity of the entire assembly. This step demands precise handling and specialized equipment to maintain the accuracy and functionality of the device. The assembly process typically follows a standardized procedure to ensure uniformity and quality control.

Creating a Simple Touchscreen Prototype

A simplified touchscreen prototype can be constructed using a resistive touch sensor, a transparent conductive layer, and a display panel. A resistive sensor sheet is affixed to the display panel, with appropriate electrical connections made. The display panel can be a simple LCD panel. A suitable adhesive is used to bond the sensor to the display. Testing and calibration are crucial to ensure accurate touch input and display functionality.

A simple prototype might use readily available materials and tools, but industrial production requires more sophisticated equipment and specialized techniques.

Examples of Manufacturing Techniques

- Chemical Vapor Deposition (CVD): CVD is a widely used technique for depositing thin films of materials, including transparent conductive oxides, onto substrates. It allows for precise control over the thickness and composition of the films, crucial for touchscreen displays.

- Physical Vapor Deposition (PVD): PVD methods, such as sputtering, are employed to deposit thin films of materials like metals or alloys onto the display panel. This technique offers excellent control over the film properties, crucial for the electrical characteristics of touch sensors.

- Screen Printing: Screen printing is a technique used to apply conductive inks or other materials to the display panel. This process is cost-effective and suitable for mass production. However, precision can be limited.

Future Trends and Innovations: Development Of Touchscreen Technology

Touchscreen technology is constantly evolving, driven by the need for more intuitive, responsive, and versatile user interfaces. Emerging trends focus on enhancing existing capabilities and exploring entirely new possibilities. This dynamic landscape promises significant advancements in various industries, from consumer electronics to healthcare.

Emerging Trends in Touchscreen Technology

Advancements in touchscreen technology are multifaceted, encompassing improvements in responsiveness, accuracy, and user experience. These trends include the exploration of new input methods, advancements in display technology, and increased integration with other technologies. A key focus is on creating seamless interactions that adapt to diverse user needs.

Potential Future Applications of Touchscreen Technology

The diverse applications of touchscreen technology are expanding beyond the traditional realm of consumer electronics. Innovative applications are emerging in areas like healthcare, manufacturing, and even in the realm of artistic expression. The integration of touchscreens with other technologies, such as augmented reality and artificial intelligence, opens up entirely new possibilities.

Ongoing Research and Development Efforts

Ongoing research and development initiatives are dedicated to pushing the boundaries of touchscreen technology. Researchers are investigating novel materials and manufacturing processes to improve the sensitivity, durability, and cost-effectiveness of touchscreens. Exploration of new interaction methods, such as haptic feedback and gesture recognition, is also a significant area of focus.

Potential Impact on Various Industries

The evolving touchscreen technology holds the potential to revolutionize numerous industries. In healthcare, touchscreen interfaces can lead to more intuitive medical equipment, improving diagnostics and patient care. Manufacturing processes can be streamlined with interactive dashboards, optimizing production efficiency and reducing errors. The entertainment industry can expect more immersive and engaging experiences, while the design and architectural industries can leverage intuitive design tools.

In short, touchscreen technology is poised to enhance user experiences and boost productivity across a wide spectrum of industries.

Examples of Innovative Touchscreen Technologies

Several innovative touchscreen technologies are under development, demonstrating the breadth of research in this field. These include advancements in pressure-sensitive displays, allowing for more nuanced user interactions, and transparent touchscreens, enabling seamless integration with existing environments. For instance, researchers are exploring the use of voice and eye-tracking to enhance the interaction capabilities of touchscreen devices.

Future Projections

Predicting the precise future of touchscreen technology is challenging. However, based on current research and development efforts, several projections can be made. Touchscreens will likely become even more ubiquitous, integrating seamlessly into everyday objects and environments. Their sensitivity and responsiveness will continue to improve, leading to more intuitive and efficient user interactions. The potential applications are vast and are likely to significantly reshape various industries.

Design Considerations

Source: study.com

Designing user interfaces (UIs) for touchscreen devices requires careful consideration of numerous factors. A well-designed UI enhances user experience, making interaction intuitive and enjoyable. This section delves into key design principles and considerations for creating effective touchscreen applications.

Factors Influencing UI Design

Effective touchscreen UI design hinges on several crucial factors. Understanding the target audience, device characteristics, and overall application goals are fundamental. Contextual factors like the user’s environment and task requirements also play a vital role in shaping the design. Furthermore, designers must consider the user’s technical proficiency and prior experience with similar applications.

Intuitive Design Principles

Intuitive design is paramount for touchscreen applications. Users should readily understand the functionality of elements and their interactions. Employing consistent design patterns, clear visual cues, and logical arrangement of controls enhances usability. Visual hierarchy, color schemes, and typography also play significant roles in guiding user attention and fostering an intuitive interaction. Good design fosters a natural flow of interaction, reducing the cognitive load on the user.

User-Centered Design

User-centered design (UCD) is essential in developing effective touchscreen applications. It involves actively involving users in the design process through various methods, such as user testing and feedback collection. By incorporating user feedback, designers can identify areas for improvement and tailor the UI to meet the needs of the target audience. This iterative approach leads to more effective and user-friendly applications.

Accessibility Considerations

Accessibility is a critical aspect of touchscreen UI design. Ensuring that the application is usable by individuals with disabilities is paramount. This involves considering factors such as screen reader compatibility, alternative text for images, and adjustable font sizes. Designing with diverse user needs in mind fosters inclusivity and expands the application’s potential user base. Compliance with accessibility guidelines like WCAG (Web Content Accessibility Guidelines) is essential.

Best Practices for Different Touchscreen Devices

| Device Type | Screen Size | Interaction Style | Design Considerations |

|---|---|---|---|

| Smartphones | Small screens (typically 4-6 inches) | Single-handed interaction, tap-based gestures | Prioritize simplicity, use icons and concise text, leverage on-screen keyboards for input, consider pinch-to-zoom for images. |

| Tablets | Medium screens (typically 7-10 inches) | Multi-finger gestures, more space for controls | Employ larger icons and buttons, support multi-column layouts, accommodate for different viewing angles. |

| Wearable Devices | Small screens (typically 1-2 inches) | Limited interaction, often relying on simple gestures | Prioritize quick and intuitive interactions, leverage haptic feedback, employ compact layouts. |

| Large-format Touchscreens | Large screens (over 10 inches) | Multiple user interactions, complex applications | Enable zooming and panning for large datasets, support multi-user interactions, and provide visual aids and guides. |

This table Artikels key considerations for designing interfaces across various touchscreen devices. Understanding the specific characteristics of each device type is crucial for creating a tailored and effective user experience.

Challenges and Limitations

Touchscreen technology, while ubiquitous, faces inherent limitations that impact its development and widespread adoption. These limitations, ranging from technological hurdles to environmental concerns, require ongoing research and innovative solutions. Understanding these challenges is crucial for future improvements and responsible implementation.Despite advancements, several factors hinder the optimal performance and widespread application of touchscreen technology. These challenges encompass the technical aspects of the technology itself, its environmental footprint, and the need for continuous improvement to meet evolving user needs.

Technical Limitations

The precise nature of touch sensing remains a challenge. Current technologies often struggle with differentiating between multiple touches, detecting the precise location and pressure of each contact, and maintaining responsiveness in dynamic or complex interactions. Inaccurate or delayed responses can lead to frustration and reduced user experience. For example, a touchscreen failing to register a tap in a crucial moment of a game or application could impact the user’s enjoyment and satisfaction.

Manufacturing and Material Concerns

Manufacturing processes for high-quality touchscreens often involve specialized materials and complex techniques. The cost of production, particularly for advanced or larger displays, can be a significant barrier to wider adoption. Further, the availability and sustainability of these materials are critical factors. For example, the increasing demand for rare earth elements in certain manufacturing processes raises concerns about supply chain vulnerabilities.

Environmental Impact

The production of touchscreen displays, encompassing the extraction of raw materials, manufacturing processes, and energy consumption, contributes to environmental concerns. The disposal of these devices, containing potentially hazardous materials, also presents environmental challenges. Proper recycling and disposal procedures are crucial to mitigate the negative environmental impact. For example, the electronics industry, as a whole, generates substantial e-waste, posing a risk to human health and the environment.

User Experience Issues

Touchscreen technology can sometimes struggle to fully emulate the tactile experience of physical input. Users accustomed to physical keyboards or buttons might find the transition to touchscreens challenging, particularly for precise tasks or complex input. For instance, tasks requiring meticulous input, such as graphic design or programming, might not be optimized for touchscreen interfaces.

Ongoing Research and Solutions

Active research focuses on enhancing touch sensitivity and accuracy. Advanced sensing techniques, including capacitive and pressure-sensitive technologies, are being explored to improve the reliability and responsiveness of touchscreens. Further, the development of new materials and manufacturing processes aims to reduce production costs and environmental impact. For example, research into alternative materials and production methods for touchscreens seeks to reduce the use of hazardous substances and lower the overall carbon footprint.

Materials and Components

The materials used in touchscreen displays are meticulously chosen to balance functionality, cost-effectiveness, and performance. Different materials are used for various components, each contributing to the overall touch response, durability, and visual quality of the display. Understanding the properties of these materials is crucial for optimizing the design and performance of touchscreen technology.The selection of materials for touchscreen devices is driven by a complex interplay of factors.

Consideration is given to the material’s mechanical properties, including its ability to withstand stress and pressure, and its optical properties, influencing the display’s clarity and color reproduction. Chemical resistance and cost-effectiveness are also significant considerations.

Material Properties for Touch Sensing

The primary materials used in touch sensing layers are designed for their responsiveness and accuracy. These layers detect the pressure and location of a touch input, translating it into a digital signal for the device to process. Different types of materials offer varying levels of sensitivity, response time, and durability.

Types of Materials in Touchscreen Displays

- Glass: Toughened glass, often used as the protective layer, provides a robust and scratch-resistant surface for the touchscreen. Its transparency ensures clear visibility of the display content. The specific type of glass used, along with its manufacturing process, affects the overall strength, clarity, and cost of the touchscreen.

- Polymers: Polymers, including various types of plastics, play a vital role in the touch-sensing layer. They can be designed to be highly sensitive to touch inputs, providing a smooth and responsive user experience. Different polymer types offer varying levels of flexibility, transparency, and cost-effectiveness. Polyimide, for example, is often employed due to its excellent dielectric properties.

- Conductive Materials: Conductive materials, such as indium tin oxide (ITO), are used to create transparent electrodes within the touch-sensing layer. These electrodes detect the touch input and convert it into an electrical signal. The conductivity and transparency of the material are crucial for accurate touch detection. Alternatives like carbon nanotubes and graphene are emerging as promising materials due to their higher conductivity and lower cost potential.

- Adhesive Materials: Adhesives are essential for bonding different layers of the touchscreen display. The adhesive must be strong enough to hold the layers together under stress but also flexible enough to allow for some degree of movement. They also need to be compatible with the other materials used in the display to prevent degradation or reactions over time.

These adhesives are carefully selected to ensure the long-term stability of the device.

Material Selection in Touchscreen Design

Material selection is critical to the overall performance and design of touchscreen displays. The choice of material impacts not only the accuracy and speed of touch response but also the durability, cost, and visual clarity of the device. For instance, using a more durable glass type can increase the lifespan of the touchscreen, whereas choosing a specific polymer can improve the sensitivity to touch.

Material properties influence the display’s overall performance, impacting its market competitiveness.

Summary Table of Touchscreen Materials

| Material Type | Key Properties | Applications |

|---|---|---|

| Toughened Glass | High strength, scratch resistance, transparency | Protective layer |

| Polymers (e.g., Polyimide) | Flexibility, transparency, sensitivity | Touch-sensing layer |

| Indium Tin Oxide (ITO) | High conductivity, transparency | Transparent electrodes |

| Adhesives | Strong bond, flexibility, compatibility | Bonding layers |

Last Recap

In conclusion, the development of touchscreen technology has been a fascinating journey marked by innovation and adaptation. From humble beginnings to widespread adoption, the technology continues to evolve, pushing boundaries and shaping our interaction with the digital world. The future promises even more exciting possibilities, with ongoing research and development driving further advancements.

Post Comment